LIPOSOMAL IRON

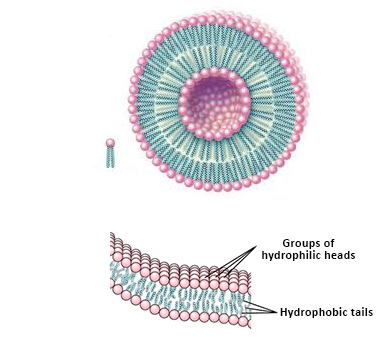

A liposome is a vesicle structure with spherical shape composed of one or several phospholipid bilayers. The image illustrates the composition of a simple liposome composed by a mono lamellar phospholipid bilayer.

A liposome is a vesicle structure with spherical shape composed of one or several phospholipid bilayers. The image illustrates the composition of a simple liposome composed by a mono lamellar phospholipid bilayer.

Figure 1: Representation of the structure and formation of the phospholipid bilayer in a simple liposome.

The formation and structure of the liposomes is due to the amphiphilic nature (with hydrophilic and hydrophobic regions) of the phospholipids that compose it, whose homologous regions are united in aqueous medium, so it is essentially a mechanical process of phospholipids hydration.

When the encapsulated compound is soluble in water, it is positioned inside the structure while in the case of a hydrophobic compound, would be placed in the liposome membrane

The production of liposomes is realized by the following processes:

- Evaporation in reverse phase

- Ultrasonication of emulsified phospholipids

- Microfluidization

The production processes and the choice of the constituents of the liposome are very important factors that determine the effectiveness of microencapsulation, the characteristics of the membrane and structure and liposomal size. The suspension obtained by this process can be lyophilized to obtain microcapsules powder.

This innovative process has generated interest because of the possibility of designing liposomes “customized” with multiple functions and that act as carriers of active ingredients. The purpose of modulating the liposomes by using factors such as temperature, pH, redox potential or affinity for a specific receptor, is to optimize the effectiveness and specificity of the active site of action. Liposomal technology has an excellent acceptance being approved for production of antivirals, antibiotics, enzyme products, food supplements and vaccines.

MICROENCAPSULATION OF IRON COMPOUNDS

Among the numerous applications of liposomes we find the encapsulation of elements and micronutrients such as minerals and vitamins. There are other processes of microencapsulation but the liposomal technique is by far the best one because its properties give it the following advantages:

- High product stability particularly in the gastrointestinal tract.

- Ability to modulate the release of the microencapsulated content under certain conditions, specifically adapted to the needs of the product.

The choice of liposomal microencapsulation process for FORTIFERRUM®+ was made because of the following advantages of this technique:

- To promote iron absorption using more efficient parallel mechanisms such as the M cells;

- Conceals the characteristic of the iron compounds which are responsible for the therapeutic abandonment besides the metallic taste;

- To reduce pro-oxidant effect of iron on protein and dietary lipids;

- To reduce interactions with elements that inhibits absorption as tannins, polyphenols and phytates in the diet;

- To reduce significantly the irritation of the gastric mucosa often associated with the intake of iron supplements.

Iron compounds are elements that present an optimal microencapsulation capacity due to its hydrophilic nature which allows them to be retained in the inside of the liposome. It has been specifically studied the stability of microencapsulated iron products and these studies showed that if the components used in encapsulation are water soluble, the active protection against oxidation is not optimal. For this reason, it has made a microencapsulation process using hydrogenated oils that provide effective protection of assets. The coating used to encapsulate the iron allows a controlled release in the gastrointestinal tract, besides allowing encapsulates more than one functional asset increasing the effectiveness of the product. The combination of elements with a synergistic effect as in the case of iron and vitamin C allows significantly increasing the effectiveness of the product because is a way to control that these elements will always be together and released at the same time increasing iron bioavailability.